Electrolytic Scale Collector

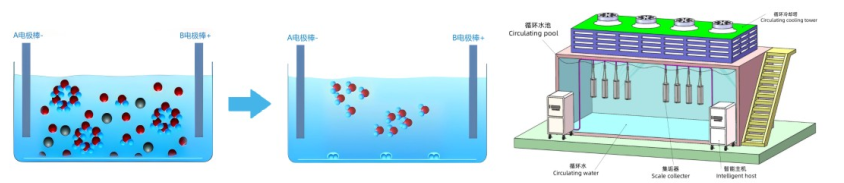

The principle of operation of an electrolytic anti-scaling device is based on the use of an electric current to prevent scale formation or remove scales that have formed in water systems such as pipes, boilers, or heat exchangers. This method is commonly used in water treatment systems to treat limescale, which forms when minerals such as calcium and magnesium precipitate from hard water.

Basic operating principle:

- Electrolysis process: The device uses electrodes (usually made of stainless steel or titanium) placed in the water stream. A low voltage current is passed through the water, causing an electrochemical reaction.

- Ionization and mineral control process: The electric current disrupts the natural tendency of calcium and magnesium ions (components of limescale) to precipitate and form hard scales. This can:

Change the crystal structure of minerals so they remain in the water, preventing them from adhering to surfaces such as pipes or heating elements.

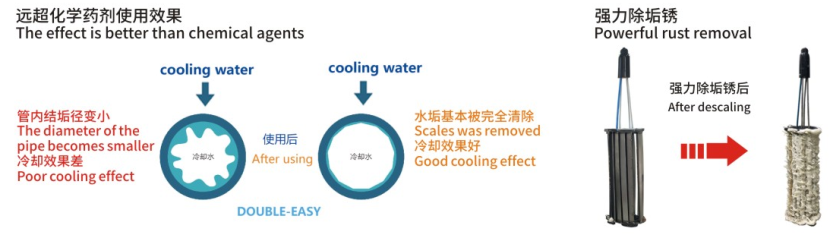

Encourages deposition onto the electrodes rather than onto the surface of the system, where the scale can then be cleaned off periodically. - Prevents scale formation: By changing the way calcium and magnesium crystallize, electrolysis reduces the adhesion of these minerals, thereby preventing the build-up of hard deposits within the system.

- Breaks down existing deposits: Some systems claim that the electric field created by electrolysis can weaken the bonds of existing deposits, allowing them to be easily removed or gradually dissolved over time.

- Produces Hydrogen and Oxygen Gases: During electrolysis, water (H₂O) can be split into hydrogen (H₂) and oxygen (O₂) gas. In some systems, these gases can help loosen or loosen deposits by creating microbubbles, which physically disturb the deposits.

Key Benefits:

- Chemical-Free Process: Electrolytic descaling equipment does not require the use of additional chemicals.

- Energy Efficient: Uses minimal energy compared to traditional mechanical methods.

- Environmentally Friendly: Since no chemicals are used, the process is more sustainable and environmentally safe.

Applications:

- Water Heaters

- Boilers

- Cooling Towers

- Heat Exchangers

- Conveyor Pipes industry

In summary, electrolytic antiscalants extend the life and improve the performance of water-related systems by minimizing or preventing scale buildup using electrical energy.

Principle of electrolytic scale collector

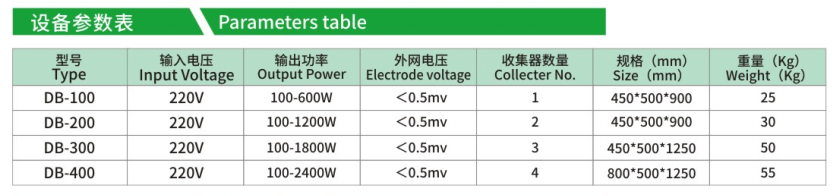

Specifications:

Some pictures

Reviews

There are no reviews yet.