Centrifugal filtration equipment Nikuni

Contact

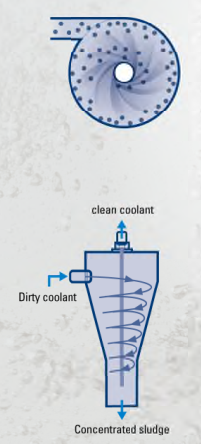

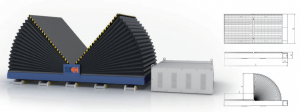

Nikuni filter equipment uses centrifugal filtration method. Sludge-containing water is supplied by the pump, which moves vortex inside the wall of the VDF filter. While rotating under centrifugal pressure, the heavier sludge layer will be pushed down the sludge tube, the clean water will be pushed up at the center of the VDF filter.

Video introduction of VDF Nikuni

https://www.youtube.com/watch?v=YseZA9VAo5o

Explanation of VDF . Transparency

https://www.youtube.com/watch?v=hE34-a5Q4fc&feature=youtu.be

The effect of the Nikuni . centrifugal filter device

- Reduce operating costs

- Reduced filter replacement work: with the VDF, there is no need to replace the filter

- Reduced fluid replacement work (cyclical)

- The life of the blade and grinding wheel: the VDF machine ensures that the cooling water is as clean as the original, so it can prolong the life of the blade.

- Reduce defective products, improve product quality

- In the process of processing, using cooling water without residue will scratch the surface of the product, causing waste

- Causing defective products after surface treatment such as painting, plating, etc.

- Protect and prolong the life of the machine

Application of VDF . machine

- Coolant for machining centers, double-head grinders, vertical grinders

- Cooling water for cooling towers, casting molds

- Machine cleaner: cleaning faucet, high pressure and ultrasonic wave

- Heat treatment water: hardening equipment, quenching products

- Factory wastewater

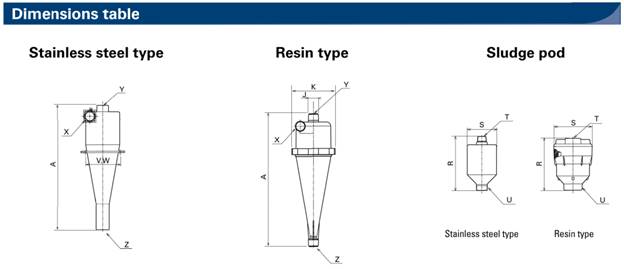

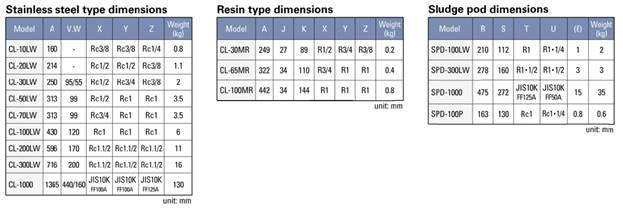

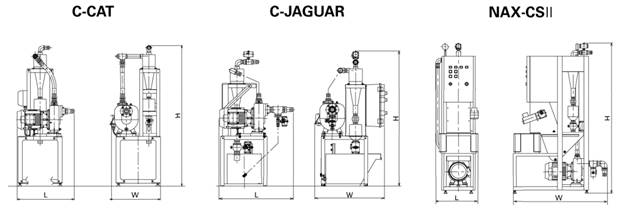

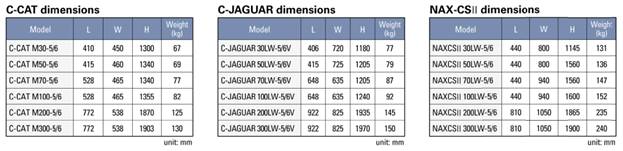

Standard specification

Reviews

There are no reviews yet.