Laser Mold Cleaning Machine

Laser Mold Cleaning Machine is a modern device that uses laser technology to remove dirt, grease, rust or impurities on the surface of the mold. This is the optimal solution for manufacturing industries such as automobiles, plastics, metal casting, electronics, etc.

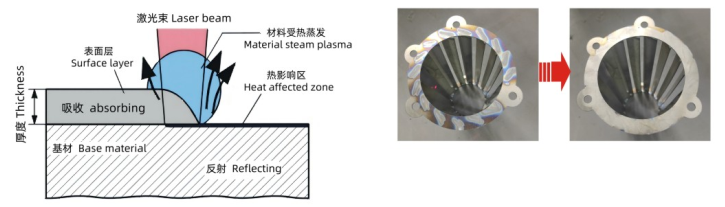

How it works:

- Laser emission:

The machine emits a high-energy laser beam and is adjusted to suit the type of material to be cleaned. - Interaction between laser and surface:

- When the laser comes into contact with the impurity layer (such as oil, dust, rust), it will absorb energy and heat up rapidly.

- The impurity is broken chemically and physically, leading to evaporation, vaporization or separation from the surface.

- Impurity removal:

- Impurities are burned or shot off the surface due to thermal pressure.

- No damage to the underlying material layer thanks to the ability to precisely adjust the laser energy.

- Automatic cleaning system:

- Some machines also integrate a vacuum or compressed air system to remove impurities after being processed.

Cleaning principle of laser mold cleaning machine

Advantages of Laser mold cleaning machine:

- High efficiency:

- Remove impurities quickly without damaging the mold surface.

- Suitable for complex and difficult-to-reach parts.

- No chemicals used:

- Safe and environmentally friendly because no chemical solvents are required.

- No secondary waste generated.

- Protect the mold surface:

- Non-abrasive laser technology helps maintain precision and mold life.

- Cost savings:

- Reduce cleaning time and maintenance costs.

- Limit the need to replace new molds.

- Easy to operate:

- The device is compactly designed, easy to use, and can be integrated into the production line.

Applications:

- Cleaning plastic molds, rubber molds, metal casting molds.

- Removing rust on machinery or metal parts.

- Cleaning old coatings, paints or oxides on the surface face.

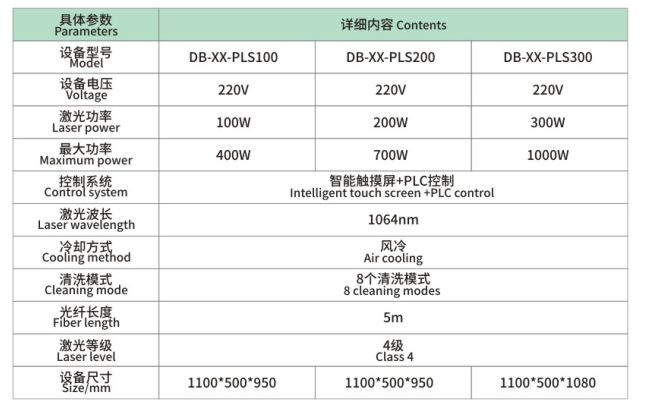

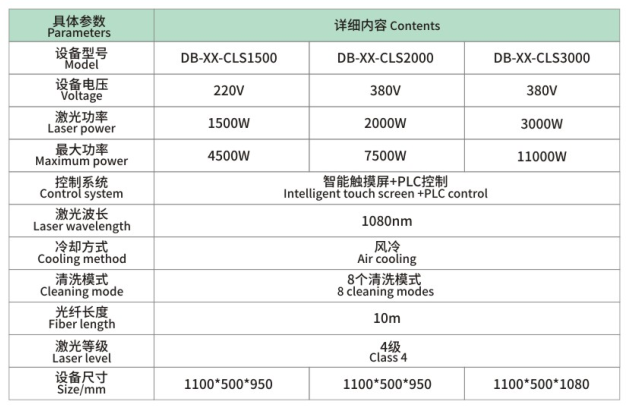

Specifications:

Reviews

There are no reviews yet.