Die Spotting Press, YC High Precision Series

Contact

A reasonably designed die spotting press makes the inspection and repair of complex molds much easier.

The YC die spotting press features a high precision, and is equipped with four spotting oil cylinders arranged in a square. This ensures a more uniform mold plate force, and a smaller deformation coefficient. All of these are not things found in a traditional spotting machine where the spotting oil cylinders are arranged in a line.

We provide 9 types of die spotting presses, with the pressure ranging from 68T to 600T, thus ensuring they can handle multiple mold types, including die casting molds, injection molds, stamping molds and more.

According to different pressure levels, we provide 11 types of machines with sizes from 80T to 800T. The size of the mixed mold that can be processed is 1.5m×1.2m.

The mold detector is a large-sized equipment. The small mold detector takes up very little vertical space and is less than 4m high. However, the maximum length and height of the machine can reach nearly 10 meters. Therefore, when choosing equipment, customers need to pay attention to their needs and space.

- Pressing capacity: 80 tons

- Opening capacity: 22 tons

- Turning capacity: 2.5 tons

- Push capacity: 2.2 tons

- Pressing capacity: 120 tons

- Opening capacity: 25 tons

- Turning capacity: 4 tons

- Push capacity: 2.2 tons

- Pressing capacity: 160 tons

- Opening capacity: 38 tons

- Turning capacity: 8 tons

- Push capacity: 6.3 tons

- Pressing capacity: 200 tons

- Opening capacity: 45 tons

- Turning capacity: 10 tons

- Thrust capacity: 6.3 tons

- Pressing capacity: 260 tons

- Opening capacity: 50 tons

- Turning capacity: 10 tons

- Push capacity: 6.3 tons

- Pressing capacity: 300 tons

- Opening capacity: 56 tons

- Turning capacity: 18 tons

- Push capacity: 6.3 tons

- Pressing capacity: 350 tons

- Opening capacity: 70 tons

- Capacity tipping: 25 tons

- Push capacity: 11.2 tons

- Pressing capacity: 400 tons

- Opening capacity: 80 tons

- Turning capacity: 25 tons

- Push capacity: 11.2 tons

- Pressing capacity: 500 tons

- Opening capacity: 120 tons

- Turning capacity: 30 tons

- Push capacity: 21.5 tons

- Pressing capacity: 600 tons

- Opening capacity: 150 tons

- Turning capacity: 35 tons

- Push capacity: 21.5 tons

- Pressing capacity: 800 tons

- Opening capacity: 190 tons

- Turning capacity: 105 tons

- Push capacity: 21.5 tons

- Pressing capacity: 1000 tons

- Opening capacity: 250 tons

- Turning capacity: 105 tons

- Push capacity: 21.5 tons

- Pressing capacity: 1200 tons

- Opening capacity: 400 tons

- Turning capacity: 150 tons

- Push capacity: / tons

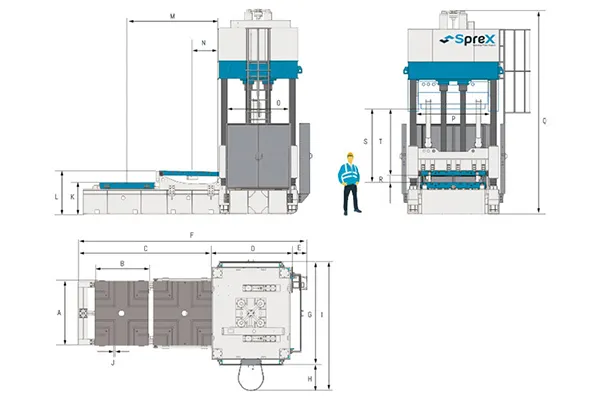

| Dòng | SX80YC | SX120YC | SX160YC | SX200YC | SX260YC | SX300YC | SX350YC | SX400YC | SX500YC | SX600YC | SX800YC | SX1000YC | SX1200YC |

| A | 1000 | 1400 | 1300 | 1800 | 2000 | 2200 | 2800 | 3000 | 3100 | 3500 | 4200 | 5000 | 6500 |

| B | 800 | 1100 | 1300 | 1500 | 1600 | 1800 | 2200 | 2000 | 2100 | 2500 | 3500 | 4200 | 4600 |

| C | 2320 | 3080 | 3320 | 3730 | 3740 | 4410 | 4880 | 4840 | 4940 | 5945 | 8485 | 9215 | 10015 |

| D | 1270 | 1720 | 2000 | 2200 | 2200 | 2680 | 2880 | 2960 | 3160 | 3560 | 4560 | 5220 | 5620 |

| E | 595 | 580 | 430 | 430 | 430 | 610 | 610 | 320 | 320 | 320 | 470 | 475 | 475 |

| F | 4180 | 5380 | 5750 | 6360 | 6370 | 7700 | 8370 | 8120 | 8420 | 9825 | 13515 | 14910 | 16110 |

| G | 1850 | 2395 | 2680 | 2880 | 3080 | 3510 | 4110 | 4390 | 4550 | 5000 | 5940 | 6820 | 8590 |

| H | 765 | 765 | 765 | 765 | 765 | 715 | 715 | 715 | 715 | 715 | 715 | 715 | 715 |

| I | 2615 | 3160 | 3425 | 3625 | 3845 | 4225 | 4826 | 5105 | 5265 | 5715 | 6655 | 7535 | 9305 |

| J | 22 | 22 | 28 | 28 | 28 | 36 | 36 | 36 | 36 | 36 | 42 | 42 | 42 |

| K | 570 | 715 | 805 | 875 | 875 | 985 | 1035 | 1085 | 1155 | 1275 | 1610 | 1665 | 1665 |

| L | 775 | 995 | 1085 | 1175 | 1175 | 1305 | 1580 | 1625 | 1730 | 1875 | 1995 | 2184 | 2184 |

| M | 1485 | 2090 | 2210 | 2520 | 2520 | 3025 | 3360 | 3320 | 3370 | 4180 | 6120 | 6590 | 7140 |

| N | 440 | 670 | 640 | 750 | 750 | 910 | 1030 | 990 | 990 | 1350 | 1790 | 2130 | 2330 |

| O | 940 | 1280 | 1500 | 1700 | 1700 | 2060 | 2260 | 2260 | 2400 | 2800 | 3720 | 4300 | 4700 |

| P | 1210 | 1645 | 1860 | 2060 | 2260 | 2550 | 3150 | 3340 | 3470 | 3900 | 4600 | 5400 | 6900 |

| Q | 3690 | 4630 | 5240 | 5695 | 5780 | 6860 | 7205 | 7405 | 8525 | 9275 | 11855 | 12300 | 13400 |

| R | 150 | 200 | 200 | 200 | 200 | 200 | 400 | 400 | 400 | 400 | 100 | 100 | 100 |

| S | 1150 | 1500 | 1700 | 1900 | 1900 | 2300 | 2500 | 2500 | 3000 | 3200 | 4000 | 4300 | 4700 |

| T | 1000 | 1300 | 1500 | 1700 | 1700 | 2100 | 2100 | 2100 | 2600 | 2800 | 3900 | 4200 | 4600 |

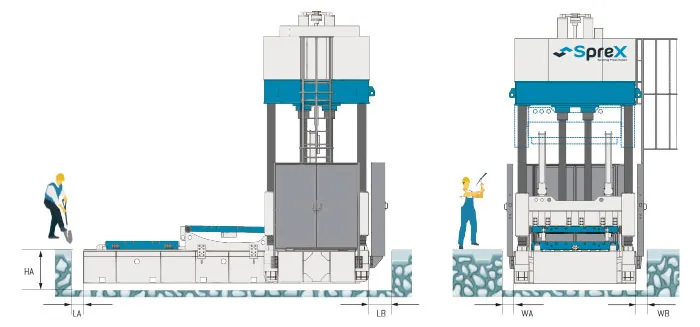

| HA | 500 | 670 | 750 | 800 | 800 | 900 | 900 | 1100 | 1100 | 1100 | 1750 | 1450 | 1450 |

| LA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| LB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

- Designed with a guide column structure, ensuring higher precision during high-pressure molding as well as easier adjustment of the parallelism of the rollers.

- All moving parts are equipped with graphite bronze guide sleeves for oil-free and self-lubricating operation, making the equipment clean and environmentally friendly.

- Equipped with practical and reliable fault detection, alarm system and low-pressure mold protection function.

- The lower machine table is equipped with high-precision positioning and lifting devices, improving the operating efficiency.

- There are 4 mold clamping cylinders, distributing the force evenly during high-pressure mold closing and minimizing the deformation coefficient.

- The movement of the roller is detected by the German SIKO magnetic strip, providing accurate positioning.

- Equipped with mechanical safety protection devices to protect the mold and machine.

During the mold scanning process, the operator only needs to place two corresponding molds on the roller base and the upper press plate. When the molds are fixed in place by the hydraulic clamping system, the equipment will start to work. The roller base moves forward, while the upper press plate moves up and turns 180 degrees. In this way, the two-piece mold will complete the positioning work at its position effectively.

Four guide posts ensure the stable operation of the entire equipment, and the parallel position of the mold can be adjusted simply by moving the position of the guide post nut, thus ensuring high precision. We also use an elastic mold plate to ensure high precision under high pressure conditions.

When the roller pin returns to its original position, the hydraulic machine safety device will automatically engage and lock the roller pin, making the operation of the mold and machine safer and more secure.

Using the optional servo motor for control can help reduce the oil temperature and the energy consumption of the mold detector.

Magnetic plate molds are used in connection with the mold detector to achieve fast mold change fast and accurate.

We provide a variety of hydraulic clamping systems suitable for mold detection machines, helping customers to change molds quickly and accurately.

Be the first to review “Die Spotting Press, YC High Precision Series” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.