FW Series Hydraulic Clamping System

Contact

The FW series hydraulic clamping system is used for mold clamping operations with the clamping direction from left to right, assisting the operator to make quick changes during mold production. This significantly shortens the time required to change molds and makes it an essential equipment to improve the efficiency of injection molding and die casting mold production.

Technical specifications

FW2

- Clamping force (25MP): 20 kn

- X-cycle: 7 mm

- Y-clamp cycle: 3 mm

- Z-safe cycle: 4 mm

FW4

- Clamping force (25MP): 40 kn

- X-stroke: 7 mm

- Y-stroke: 3 mm

- Z-safety stroke: 4 mm

FW6

- Clamping force (25MP): 60 kn

- X-stroke: 8 mm

- Y-stroke: 4 mm

- Z-safety stroke: 4 mm

FW10

- Clamping force (25MP): 100 kn

- X-cycle: 8 mm

- Y-clamp cycle: 3 mm

- Z-safety cycle: 5 mm

FW16

- Clamping force (25MP): 160 kn

- X-cycle: 8 mm

- Y-clamp cycle: 3 mm

- Cycle Z safety: 5 mm

FW25

- Clamp force (25MP): 250 kn

- X-cycle: 8 mm

- Y-cycle: 3 mm

- Z-safe cycle: 5 mm

FW50

- Clamp force (25MP): 500 kn

- X-stroke: 8 mm

- Y-stroke: 3 mm

- Z-safe stroke: 5 mm

Machine series specifications

| Series | Clamping force(25MP) | X-stroke | Y-stroke | Z-safe stroke | Hydraulic clamp cylinder mass | Weight |

| KN | mm | mm | mm | cm3 | kg | |

| FW2 | 20 | 7 | 3 | 4 | 6.5 | 2 |

| FW4 | 40 | 7 | 3 | 4 | 13 | 4.8 |

| FW6 | 60 | 8 | 4 | 4 | 21 | 7.2 |

| FW10 | 100 | 8 | 3 | 5 | 33 | 13 |

| FW16 | 160 | 8 | 3 | 5 | 50 | 23 |

| FW25 | 250 | 8 | 3 | 5 | 88 | 36 |

| FW50 | 500 | 8 | 3 | 5 | 173 | 80 |

Product selection

Customers can choose the product line and the corresponding number of clamps depending on their usage needs.

| Machine capacity | Technical parameters of the hydraulic clamping system force | Thickness of the mold plate(mm) | |||

| Fixed roller | Quantity | Moving roller | Quantity | ||

| 60-120 | FW2 | 4 | FW2 | 4 | 25 |

| 160-250 | FW4 | 4 | FW4 | 4 | 30 |

| 280-320 | FW6 | 4 | FW6 | 4 | 30 |

| 350-600 | FW10 | 4 | FW10 | 4 | 40 |

| 650-850 | FW16 | 4 | FW16 | 4 | 50 |

| 900-1300 | FW16 | 6 | FW16 | 6 | 50 |

| 1400-1600 | FW25 | 6 | FW25 | 6 | 50 |

| 1800-2800 | FW25 | 8 | FW25 | 8 | 50 |

Features

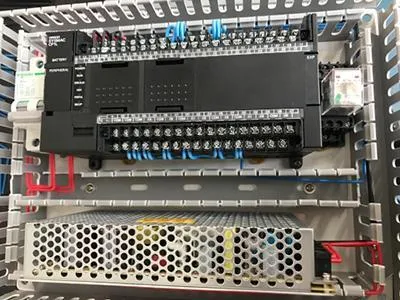

- The electrical system controller is equipped with an OMRON programmable controller, providing a user-friendly interface with multiple layers of protection for absolute safety performance.

- With high precision and safety, our hydraulic clamping system ensures optimal performance and is very easy to use.

- The clamps are arranged diagonally on the mold plate, so there are 4 independent oil lines on a pair of mold plates. If one oil line leaks, the other oil lines will not be affected.

- The pumps and valves use leak-free closed technology, thus ensuring a maximum of 168 hours of leak-free performance under 25MP system pressure.

- The power source of the pumping station is a pneumatic booster pump from Japan’s KOSMEK company, and it has a dual-pump design to improve both stability and safety during operation.

- The system pressure will be detected by 4 sets of pressure switches from the US company GEMS. The pressure pump unit will provide additional pressure when the system pressure is lower than the setting, ensuring that the system pressure is controlled within the normal range.

- This FW series hydraulic clamping system is equipped with OMRON PLC controller and SMC electrical devices, thus ensuring longer service life and better quality.

- The hydraulic clamping system and the injection molding machine have a safety interlock function, ensuring a high level of safety during use.

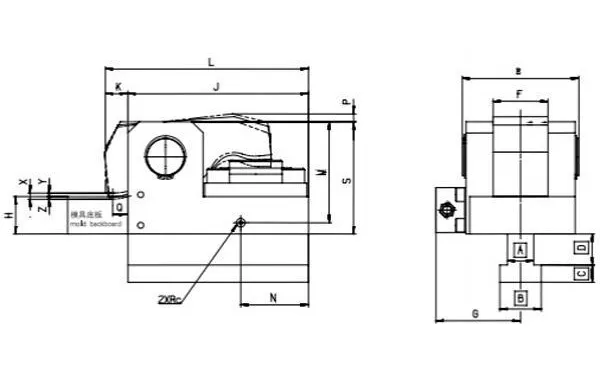

Dimensions

| Specifications | G | E | F | S | P | Q | Rc | M | N | L | K | J | H(Standard) |

| FW2 | 60 | 58 | 28 | 58 | 6.7 | 12.5 | 1/4 | 48 | 24 | 100 | 18 | 82 | 25 |

| FW4 | 66 | 73 | 40 | 80 | 8.6 | 16 | 1/4 | 70 | 35 | 138 | 23 | 115 | 30 |

| FW6 | 80 | 94 | 50 | 87 | 8.3 | 20 | 1/4 | 76 | 45 | 160 | 30 | 130 | 30 |

| FW10 | 90 | 106 | 55 | 107 | 11.1 | 20 | 1/4 | 95 | 55 | 194 | 30 | 164 | 40 |

| FW16 | 100 | 126 | 60 | 135 | 8.6 | 20 | 1/4 | 120 | 75 | 230 | 30 | 200 | 50 |

| FW25 | 113 | 155 | 73 | 150 | 10.5 | 20 | 1/4 | 135 | 90 | 270 | 30 | 240 | 50 |

| FW50 | 155 | 230 | 110 | 178 | 10.5 | 20 | 1/4 | 160 | 90 | 320 | 30 | 290 | 60 |

Note: H is the thickness of the mold base plate paired with the standard hydraulic clamp and can be customized upon request.

Be the first to review “FW Series Hydraulic Clamping System” Cancel reply

You must be logged in to post a review.

-

- Introduce

- Product

- Mold Maintenance Solutions

- KURIN Mold Water Line Cleaner

- CO2 Dry Ice Blaster for Mold Cleaning

- Mold Flipping Machine

- Lazer Welding Machine

- Electrolytic Ultrasonic Mold Cleaner

- Mold Protection Camera

- Laser Mold Cleaning Machine

- Die Spotting Press

- Die Spotting Press, YC High Precision Series

- Die Spotting Press, JM High Precision Series

- High Precision Mold Checking Machine for 3-Color Mold

- High Precision Spotting Press with Two Plate Clamping

- Hydraulic Mold Checker (Impact Simulation Type), ST Series

- Gantry Type Die Spotting Press

- Servo Motor Mold Detection Machine

- Mold Flipper / Mold Rotator

- Production support equipment

- Materials and Chemicals

- Mold Maintenance Solutions

- Services

- Customer

- Contact

Reviews

There are no reviews yet.