FY Series Hydraulic Clamping System

Contact

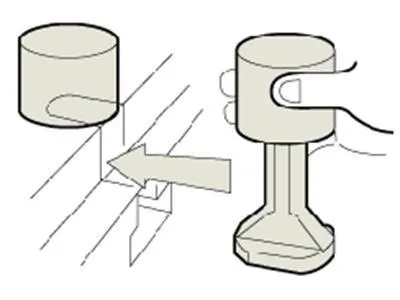

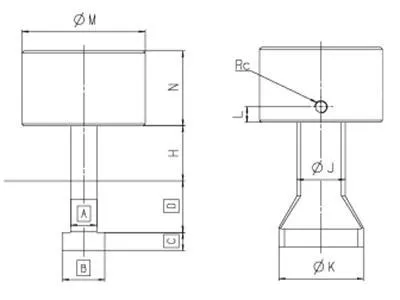

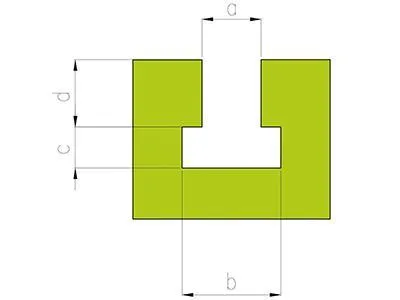

The FY series hydraulic clamping system is mainly used for clamping dies with T-slot clamps, thus reducing the time required

to change dies. Compared with other hydraulic clamping systems, high efficiency and space saving are the most attractive features of this

system as it saves a considerable amount of installation space.

The FY series hydraulic clamping system is usually used for stamping dies and is combined with suitable equipment such as stamping machines, oil

hydraulic machines, etc.

Reviews

There are no reviews yet.