CO2 Dry Ice Blaster for Mold Cleaning

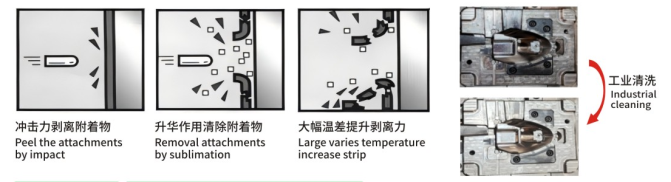

Principle of CO₂ Dry Ice Mold Cleaning Machine

CO₂ Dry Ice Mold Cleaning Machine operates on the principle of using dry ice pellets (solid CO₂) as a cleaning agent. The cleaning process is carried out according to the following mechanisms:

- Mechanical impact:

- Dry ice CO₂ is sprayed at high speed by compressed air, strongly impacting the mold surface.

- The impact force removes layers of dirt, grease or adhesives on the mold surface.

- Thermal effect:

- Dry ice CO₂ has an extremely low temperature (-78.5°C). When exposed to a hotter surface, the sudden change in temperature causes microscopic shrinkage in the dirt layers, causing them to crack and peel.

- Sublimation:

- Dry ice changes directly from a solid to a gaseous state upon impact, causing a sudden expansion in volume.

- This process aids in the separation of dirt particles from the mold surface.

- Leaves no residue:

- Dry ice sublimates completely, leaving no solid or liquid residue, leaving the mold surface clean without the need for a second cleaning step.

Principle of cleaning with CO2 dry ice blasting

Applications of CO₂ Dry Ice Mold Cleaning Machine

- Plastics and Rubber Industry:

- Remove dirt, dust, grease and waste residues on the mold surface without damaging the surface or affecting the mold gloss.

- Metal Casting Industry:

- Cleaning molds to ensure product precision and quality, especially in applications requiring high durability.

- Electronics Industry:

- Cleaning molds, circuit boards or sensitive components without affecting the structure or causing static electricity.

- Food industry:

- Remove dirt and microorganisms on food production molds without using chemicals, ensuring food hygiene and safety.

- Printing and packaging industry:

- Clean printing molds, rollers or other equipment in the packaging production line.

Advantages of this technology

- Does not damage molds: Suitable for sensitive or complex surfaces.

- Environmentally friendly: Does not use toxic chemicals and does not create secondary waste.

- Time-saving: The cleaning process is quick and does not require disassembling the mold.

- High efficiency: Completely removes stubborn stains that other methods cannot handle.

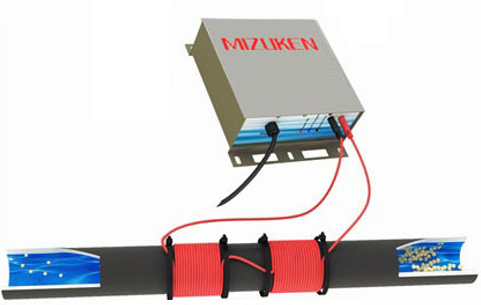

Technical specifications:

Some pictures:

Be the first to review “CO2 Dry Ice Blaster for Mold Cleaning” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.