Electrolytic Ultrasonic Mold Cleaner

Electrolytic Ultrasonic Mold Cleaners combine the principles of ultrasonic cleaning and electrolytic cleaning to effectively remove dirt, grease, and other contaminants from molds. Here’s how each principle works and how they complement each other:

Electrolytic Ultrasonic Mold Cleaners combine the principles of ultrasonic cleaning and electrolytic cleaning to effectively remove dirt, grease, and other contaminants from molds. Here’s how each principle works and how they complement each other:

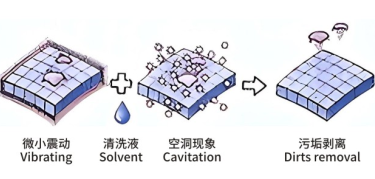

- Ultrasonic Cleaning Principle:

- The ultrasonic transducergenerates high-frequency sound waves (typically in the range of 20 kHz to 100 kHz) into a cleaning solution (usually water or detergent solution).

- These sound waves create millions of microscopic cavitationbubbles in the solution. As these bubbles implode near the mold surface, they create tiny shocks that dislodge contaminants such as grease, dirt, and scum without damaging the mold.

- Ultrasonic cleaning is very effective at cleaning complex shapes, deep grooves, and hard-to-reach areas on molds.

- Principle of Electrolytic Cleaning:

- In electrolytic cleaning, the mold is immersed in an electrolytesolution (usually an alkaline solution) that acts as an electrode.

- When an electric current is passed through the solution, contaminants on the mold surface are chemically loosened and carried away in the solution. This process helps remove oxidation, rust and stubborn deposits that ultrasonic waves cannot completely remove.

- The electrolytic reactionsoftens and dissolves the deposits, making the ultrasonic cleaning process easier.

Cleaning principle of electrolytic ultrasonic mold cleaning machine

- Combined process in electrolytic ultrasonic mold cleaning machine:

- Ultrasonic waves provide mechanical energy to dislodge dirt, while electrolysis provides chemical energy to break down stubborn dirt such as scale or rust.

- These two processes combined help improve cleaning efficiency, reduce cleaning time and ensure complete removal of dirt on the mold surface.

- This combination allows for gentle cleaning without damaging the mold, which is especially important for delicate molds or molds that require high precision.

Key benefits:

- No Abrasive: This process does not scratch or damage the mold.

- Deep cleaning: Small details and hard-to-reach areas can be reached.

- Effective on stubborn dirt: Rust, dirt and grease are effectively removed.

- High efficiency: Reduces time and effort compared to manual cleaning methods.

This technique is widely used in industries such as plastics, rubber, and die casting, where molds need to be cleaned regularly to ensure quality and production efficiency.

Specifications:

| Model | Ultrasonic power | Electrolysis current | Heating Power | Basket size | Circulating filter pump |

| DB-D45L | 1080W | 5V 20A | 1500W | 500*300*300mm | Yes |

| DB-D60L | 1200W | 5V 20A | 1500W | 500*400*300mm | |

| DB-D70L | 1440W | 5V 20A | 1500W | 500*400*350mm | |

| DB-D140L | 1800W | 5V 20A | 1500W | 700*500*400mm | |

| DB-D320L | 3600W | 5V 20A | 1500W | 1000*800*400mm |

Image:

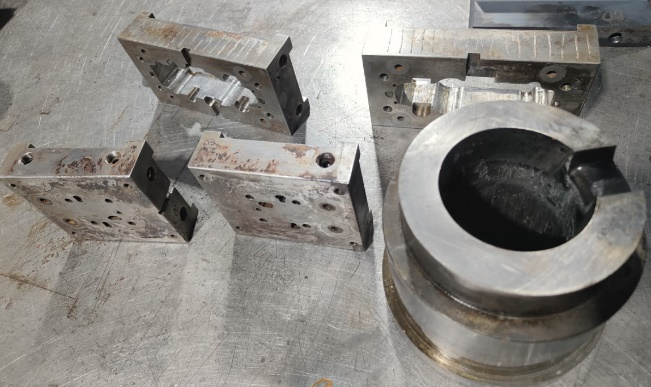

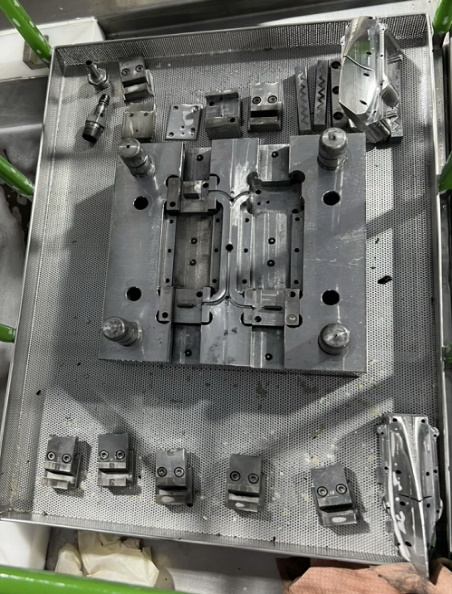

| Before | After |

|

|

|

|

Be the first to review “Electrolytic Ultrasonic Mold Cleaner” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.