Die Spotting Press, JM High Precision Series

Contact

The design fundamentals of the JM high precision series die spotting press are similar to the YC series, in that it is also equipped with four reliable guide pillars, an elastic mold plate and four spotting oil cylinders, ensuring the mold plate force is uniform and the spotting precision is high.

The main difference between the JM and YC series lies in the overall arrangement. It is important to utilize space effectively inside the plant, and in order to assist customers in doing so, we designed the JM series as a right angle types, and the YC series as a linear type. In doing so, users can choose which machine best fits their factory layout.

Depending on different pressure levels, we provide 10 types of machines with sizes from 80T to 600T. The size of the mixed mold that can be processed is 3.5m×2.5m.

- Pressing capacity: 80 tons

- Mold opening capacity: 22 tons

- Turning capacity: 2.5 tons

- Push capacity: 2.2 tons

- Pressing capacity: 120 tons

- Mold opening capacity: 25 tons

- Turning capacity: 4 tons

- Push capacity: 2.2 tons

- Pressing capacity: 160 tons

- Mold opening capacity: 38 tons

- Turning capacity: 8 tons

- Push capacity: 6.3 tons

- Pressing capacity: 200 tons

- Mold opening capacity: 45 tons

- Turning capacity: 10 tons

- Push capacity: 6.3 tons

- Pressing capacity: 260 tons

- Mold opening capacity: 50 tons

- Turning capacity: 10 tons

- Pushing capacity: 6.3 tons

- Pressing capacity: 300 tons

- Mold opening capacity: 56 tons

- Turning capacity: 18 tons

- Push capacity: 6.3 tons

- Pressing capacity: 350 tons

- Mold opening capacity: 70 tons

- Turning capacity: 25 tons

- Push capacity: 11.2 tons

- Pressing capacity: 400 tons

- Mold opening capacity: 80 tons

- Turning capacity: 25 tons

- Push capacity: 11.2 tons

- Pressing capacity: 500 tons

- Mold opening capacity: 120 tons

- Turning capacity: 30 tons

- Push capacity: 21.5 tons

- Pressing capacity: 600 tons

- Mold opening capacity: 150 tons

- Turning capacity: 35 tons

- Capacity push: 21.5 tons

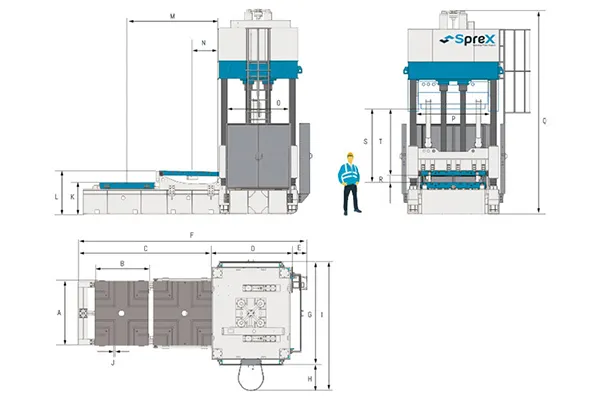

| Line | SX80JM | SX120JM | SX160JM | SX200JM | SX260JM | SX300JM | SX350JM | SX400JM | SX500JM | SX600JM |

| A | 1000 | 1400 | 1600 | 1800 | 2000 | 2200 | 2800 | 3000 | 3100 | 3500 |

| B | 800 | 1100 | 1300 | 1500 | 1600 | 1800 | 2000 | 2000 | 2100 | 2500 |

| C | 1305 | 1700 | 1920 | 2120 | 2220 | 2635 | 3230 | 3440 | 3535 | 4135 |

| D | 1530 | 2085 | 2360 | 2560 | 2760 | 3210 | 3810 | 4050 | 4280 | 4690 |

| E | 765 | 765 | 765 | 765 | 765 | 715 | 715 | 715 | 715 | 715 |

| F | 3600 | 4550 | 5045 | 5445 | 5745 | 6560 | 7755 | 8205 | 8530 | 9540 |

| G | 1240 | 1680 | 2000 | 2200 | 2300 | 2680 | 2880 | 2960 | 3200 | 3560 |

| H | 960 | 1430 | 1480 | 1680 | 1780 | 1990 | 2250 | 2210 | 2240 | 2840 |

| I | 2820 | 3740 | 3910 | 4310 | 4510 | 5280 | 5740 | 5470 | 5740 | 6700 |

| J | 22 | 22 | 28 | 28 | 28 | 36 | 36 | 36 | 36 | 36 |

| K | 537 | 682 | 762 | 832 | 832 | 905 | 975 | 1025 | 1125 | 1250 |

| L | 746 | 970 | 1040 | 1135 | 1135 | 1225 | 1515 | 1565 | 1665 | 1880 |

| M | 495 | 698 | 800 | 900 | 950 | 1115 | 1410 | 1475 | 1565 | 1790 |

| N | 445 | 670 | 640 | 750 | 850 | 910 | 1030 | 990 | 990 | 1350 |

| O | 940 | 1280 | 1500 | 1700 | 1800 | 2060 | 2260 | 2260 | 2400 | 2800 |

| P | 1120 | 1645 | 1860 | 2060 | 2260 | 2550 | 3150 | 3350 | 3470 | 3900 |

| Q | 3655 | 4580 | 5190 | 5680 | 5765 | 6780 | 7140 | 7340 | 8470 | 9275 |

| R | 150 | 200 | 200 | 200 | 200 | 200 | 400 | 400 | 400 | 400 |

| S | 1120 | 1500 | 1700 | 1900 | 1900 | 2300 | 2500 | 2500 | 3000 | 3200 |

| T | 1000 | 1300 | 1500 | 1700 | 1700 | 2100 | 2100 | 2100 | 2600 | 2800 |

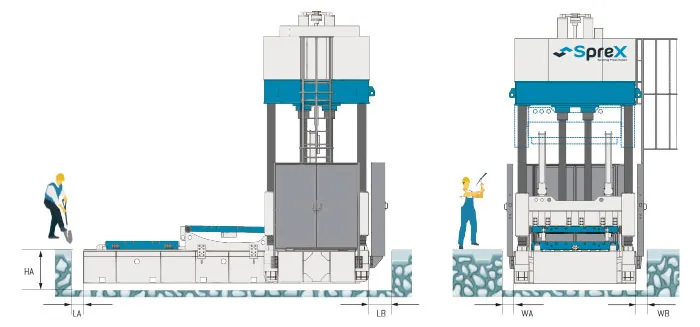

| HA | 550 | 600 | 750 | 800 | 800 | 900 | 900 | 950 | 1050 | 1100 |

| LA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

| LB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 |

- Designed with reliable guide column, ensuring higher precision during high pressure molding as well as easier adjustment of parallelism of roller.

- All moving parts are equipped with graphite bronze guide sleeves for oil-free and self-lubricating operation, making the equipment clean and environmentally friendly.

- Equipped with fault detection function, warning system and low pressure mold protection function practically and reliably to improve work safety and efficiency.

- Equipped with lower machine table with high-precision positioning and lifting devices, improving operating efficiency.

- There are four mold clamping cylinders, which distribute the force evenly during high-pressure mold closing and minimize the deformation coefficient.

- Using German-made SIKO magnetic strip to accurately detect the position of the moving roller, ensuring accurate results.

- Equipped with mechanical safety protection devices to protect valuable molds and the entire machine.

During the mold scanning process, the operator only needs to place two corresponding molds on the roller base and the upper pressing plate. Once the molds are fixed in place by the hydraulic clamping system, the equipment will start working. The roller moves forward, while the upper platen moves upward and flips 180 degrees. In this way, the two-piece mold will complete the positioning work at its position effectively.

Four guide posts ensure the stable operation of the whole equipment, and the parallel position of the mold can be adjusted simply by moving the nut position of the guide post, thus ensuring high precision. We also use elastic mold plates to ensure high precision under high pressure conditions.

When the rolling pin returns to its original position, the hydraulic machine safety device will automatically engage and lock the rolling pin, making the operation of the mold and machine safer and more secure.

Using the optional servo motor for control can help reduce the oil temperature and energy consumption of the mold detector.

Magnetic plates are used in connection with the mold detector to achieve fast and accurate mold changes.

We provide a variety of hydraulic clamping systems suitable for mold detection machines, helping customers to change molds quickly and accurately.

Be the first to review “Die Spotting Press, JM High Precision Series” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.