High Precision Mold Checking Machine for 3-Color Mold

Contact

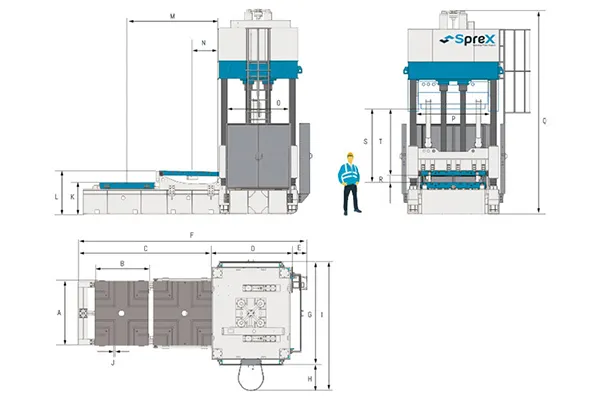

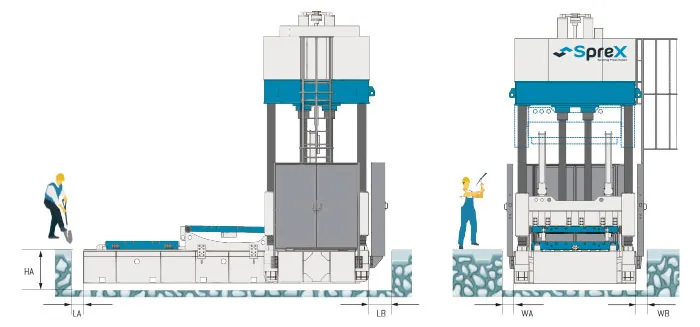

The overall structure of the high precision mold checking machine for 3-color mold is similar to that of the JM series mold checking machine, but the outstanding feature of this series is that it is equipped with a rotating device, which performs the function of changing the position during the mold checking process, so that customers can directly make 2-color molds or 3-color molds.

It is mainly used for the production of automobile lamp molds. It can also be used for the production of complex molds containing many components.

Reviews

There are no reviews yet.