KOSMEK HC Quick Mold Clamp

Contact

KOSMEK HC mold clamps provide high performance, ensuring strong holding and clamping force even without air supply.

This mold clamp has a wide range of applications, including vertical mold change and horizontal mold change. It is also suitable for horizontal injection molding machines and vertical injection molding machines with various specifications.

Technical specifications

Die clamp lines

| Lines |

HC0102

|

HC0162

|

HC0252

|

HC0402

|

HC0632

|

HC1002

|

HC1602

|

HC2502

|

||

| Mold clamping capacity | (kN) | 9.8 | 15.7 | 24.5 | 39.2 | 61.7 | 98 | 157 | 245 | |

| Strength | Air pressure | 0. 39MPa | 9.8 | 15.7 | 24.5 | 39.2 | 61.7 | 98 | 157 | 245 |

| (kN) | Air pressure | OMPa | 2.9 | 5.9 | 7.8 | 11.8 | 17.6 | 26.5 | 40.9 | 65 |

| Clamping force (kN) | Air pressure | 0. 49MPa | 7.8 | 13.7 | 19.6 | 31.4 | 48 | 75.5 | 124 | 190 |

| Atmospheric pressure | 0.39MPa | 6.9 | 11.8 | 16.7 | 26.5 | 41.2 | 63.7 | 104 | 160 | |

| Atmospheric pressure gas | OMPa | 2 | 2.9 | 4.9 | 6.9 | 9.8 | 14.7 | 23.5 | 35 | |

| Dark cycle multi | (mm) | 2 | 2 | 2.1 | 2.3 | 2.6 | 2.8 | 3 | 3.3 | |

| Clamp cycle | (mm) | 1 | 1 | 1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.3 | |

| Reserve cycle | 1 | 1 | 1.1 | 1.2 | 1.4 | 1.6 | 1.8 | 2 | ||

| Cylinder volume | Clamp side Mold | 56 | 94 | 144 | 259 | 444 | 773 | 1334 | 2468 | |

| (cm3) | Mold release face | 52 | 88 | 135 | 244 | 416 | 729 | 1262 | 2346 | |

| Pressure supply | Pressure recommended | 0.49 | ||||||||

| (MPa) | Minimum pressure | 0.39 | ||||||||

| Operating temperature | Below 70°C (above 70°C, please contact us) | |||||||||

| Operating frequency | Less than 20 times/day (or you can contact us if there is any change) | |||||||||

Machine details

| Line | ∫ |

| HC0102 | 113 |

| HC0162 | 119 |

| HC0252 | 111 |

| HC0402 | 156 |

| HC0632 | 179 |

| HC1002 | 167 |

| HC1602 | 152 |

| HC2502 | 190 |

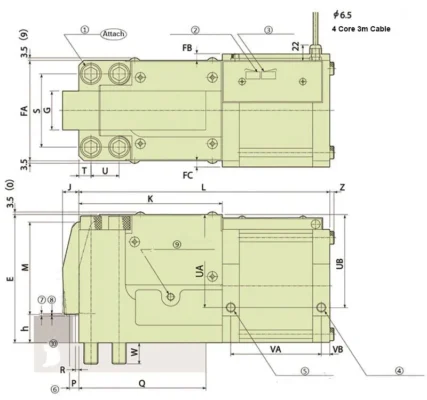

Dimensions

| Series | E | FA | FB | FC | G | J | K | L | M | P | MIN.Q | R | S | T | U | UA | UB | VA | VB | W | X | Z | (Standard)h |

| HC0102 | 66 | 50 | 6 | 6 | 16 | 10.5 | 75.5 | 159 | 39.5 | 5.6 | 46 | 15 | 33 | 8 | – | 525 | 505 | 68.5 | 7.5 | 12 | M8 | – | 20±0.3 |

| HC0162 | 76 | 60 | 6 | 6 | 19 | 12 | 86 | 174 | 48 | 6.1 | 55 | 15 | 39 | 95 | – | 60 | 58 | 73 | 7.5 | 15 | M10 | – | 20±0.3 |

| HC0252 | 85.5 | 72 | – | – | 25 | 13 | 100.5 | 195 | 48.5 | 7.4 | 84 | 2 | 50 | 11 | – | 70 | 70 | 70 | 11 | 22 | M12 | – | 30±0.3 |

| HC0402 | 1045 | 90 | – | – | 30 | 15.5 | 117.5 | 217 | 66.5 | 8.8 | 61 | 2 | 62 | 14 | – | 845 | 845 | 74.5 | 11.5 | 27 | M16 | – | 30±0.3 |

| HC0632 | 128 | 110 | – | – | 36 | 17.5 | 139.5 | 254 | 77 | 9.9 | 75 | 3 | 76 | 17 | – | 99 | 99 | 89 | 11.5 | 33 | M20 | – | 35±0.3 |

| HC1002 | 150 | 135 | 9.5 | – | 48 | 20 | 163.5 | 287 | 100.5 | 11 | 120 | 3 | 95 | 20 | – | 109.5 | 1095 | 1065 | 8.5 | 36 | M24 | – | 40±0.3 |

| HC1602 | 182 | 142 | 9.5 | 8.5 | 55 | 23 | 203 | 355 | 132 | 13 | 203 | 5 | 104 | 17 | 40 | 131.5 | 131*5 | 128 | 12 | 30 | M20 | 6 | 40±0.3 |

| HC2502 | 227 | 170 | 10 | 10 | 65 | 26 | 253 | 435 | 125.5 | 17 | 245 | 5 | 130 | 20 | 50 | 167 | 167 | 158 | 12 | 37 | M24 | 10 | 50±0.3 |

Features

- The power source is standard compressed air, so users do not need to worry about oil leakage contaminating the clamp and affecting the surrounding environment. Therefore, users do not need to worry about oil storage operation or the risk of explosion.

- All circuits use air pressure piping, which makes operation and use easier.

- Even when removing the maintenance pipe, there is no oil leakage, making maintenance and cleaning easier.

- Both KOSMEK GWA mold clamp and KOSMEK HB mold clamp have the same installation distance between holes, making the two devices compatible with each other.

- Compared with changing molds by oil pressure, this HB mold clamp has lower operating pressure, ensuring higher durability at high temperatures.

- The price of HB mold clamp is lower than that of oil pressure mold clamp, especially for long-term use.

Be the first to review “KOSMEK HC Quick Mold Clamp” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.