KURIN Mold Water Line Cleaner

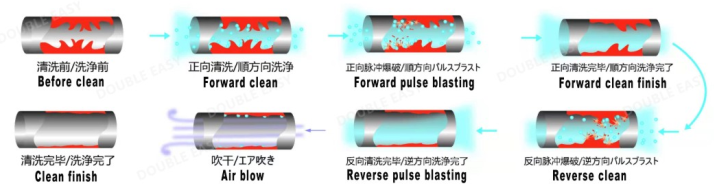

The cleaning principle of the machine is based on the use of air and water at high pressure and high speed. These two factors combine to create small air bubbles, when the air bubbles explode, they will generate a strong impact force on the surface of the dirt stuck in the pipe. This impact force helps to gradually dissolve the layers of dirt. In particular, the machine is designed for two-way flushing, ensuring comprehensive cleaning and optimal efficiency in removing dirt.

The cleaning principle of the machine is based on the use of air and water at high pressure and high speed. These two factors combine to create small air bubbles, when the air bubbles explode, they will generate a strong impact force on the surface of the dirt stuck in the pipe. This impact force helps to gradually dissolve the layers of dirt. In particular, the machine is designed for two-way flushing, ensuring comprehensive cleaning and optimal efficiency in removing dirt.

Operating principle diagram

Advantages of mold water line cleaning machine:

- No need to disassemble the mold: Save time and effort, just connect the inlet and outlet between the machine and the mold, making the cleaning process simple and convenient.

- Quick cleaning time: Only takes about 30 minutes, helping to optimize maintenance time and improve productivity.

- Water flow measurement feature: Allows effective monitoring and management of mold quality, ensuring the mold operates in optimal conditions Optimum.

- Detect leaking or clogged water lines: Timely warning to prevent mold damage, minimize repair costs and production downtime.

- Display results report: Display mold number, time, flow before and after to help the factory easily manage mold operation and maintenance.

This cleaning machine not only cleans mold water lines but is also widely used in:

- Cleaning and maintaining oil coolers, ensuring optimal performance.

- Cleaning water heaters, helping to maintain efficiency and save energy.

- Maintaining chiller systems, removing dirt and increasing equipment life.

- Cleaning air compressors, helping to reduce energy consumption and optimize performance.

- Cleaning rolling rolls membrane, ensuring the product surface meets quality standards.

- Maintain the high-frequency furnace, remove residue, help the furnace operate durably and stably.

Technical parameters

| Model | K2-15C | K6-15C | K6-22C | K6-30C | K8-30C | K8-55C |

| Cleaning fluid | Tap water or Chemical | |||||

| Control | PLC&Touch screen control | |||||

| Pipe size | 3/8”*8 | 3/8”*8 | 3/8”*8, 1”*2 | 3/8”*12, 1”*2 | 3/8”*8, 1.5”*2 | 3/8”*8, 2”*2 |

| Pump Power | 1.5 KW | 1.5 KW | 2.2 KW | 3.0 KW | 3.0 KW | 5.5 KW |

| Tank size | 50L | 100L=50L+50L | 100L=50L+50L | 100L=50L+50L | 150L=75L+75L | 150L=75L+75L |

| Dimension | 145*50*105cm | 160*50*130cm | 160*50*130cm | 160*50*130cm | 170*60*135cm | 170*60*135cm |

| Weight | 210Kg | 270Kg | 290Kg | 320Kg | 360Kg | 380Kg |

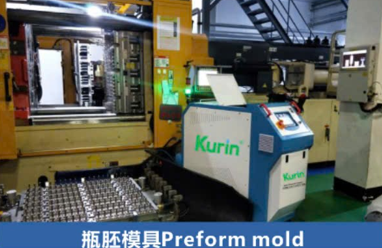

Image

| Application

|

Before | After |

|

|

|

|

|

|

|

|

|

Be the first to review “KURIN Mold Water Line Cleaner” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.