Mold Flipping Machine

Mold Flipping Machine is a supporting equipment in the industry, especially in the plastic, rubber, metal casting and mold manufacturing industries. Here are the main uses of the mold flipper:

- Supports safe and efficient mold flipping operations

- The mold flipper is used to rotate or flip large and heavy molds from 90° to 180° easily without manual intervention.

- Ensures operator safety, reduces the risk of work accidents when flipping molds by manual methods such as using cranes or forklifts.

- Protects molds and increases their lifespan

- Minimizes mechanical impact or strong impact during the mold flipping process, avoiding damage to the surface or sensitive parts of the mold.

- Maintains the accuracy and quality of the mold, helping the mold operate smoothly more durable and efficient.

- Save time and effort

- Speed up the mold flipping process, reduce preparation time in stages such as mold maintenance, cleaning, or inspection.

- Reduce the need for labor and auxiliary equipment, optimize the production process.

- Wide range of applications

The mold flipping machine is suitable for many types of molds in industries such as:

- Plastics and rubber industry: Flip plastic injection molds, rubber molds for cleaning or maintenance.

- Metal casting industry: Flip molds metal for inspection, cleaning, or changing working position.

- Mold manufacturing industry: Easily manipulate large and complex molds.

- Improve accuracy during mold flipping

- The device is designed to ensure that the mold flipping process is accurate, balanced, and does not cause mold deformation.

Advantages of mold flipping machine

- Safety: Minimizes risks during operation.

- Convenience: Easy to use with automatic or semi-automatic control system.

- High durability: The machine is solidly designed to withstand heavy loads and operate stably for a long time.

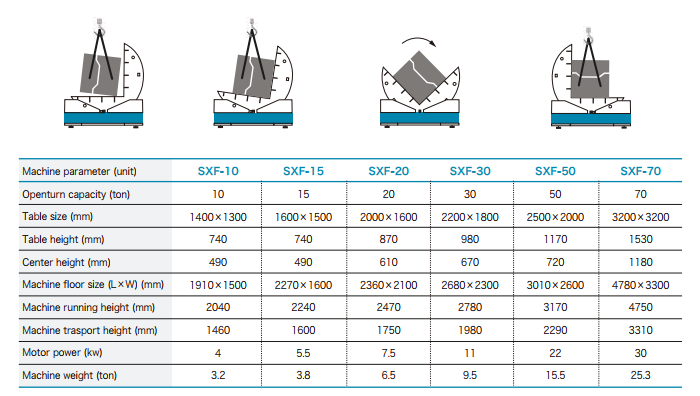

Technical parameters of the 90◦C mold flipping machine

<

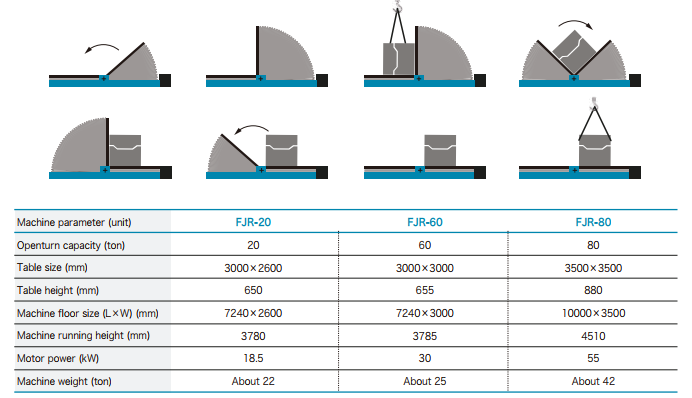

Technical parameters of the 180◦C mold flipping machine

Be the first to review “Mold Flipping Machine” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.